Risk assessment and risk reduction for machinery (Suva's method)

Do you manufacture or place machinery on the market? To place your products on the market in Switzerland or the European Union, you need to assess and reduce the risks that your machines present.Suva can help you to do this – with a reliable method and a practical tool.

Content

Short and succinct

- If your machine presents a hazard, sooner or later it will cause harm – unless protective measures are put in place.

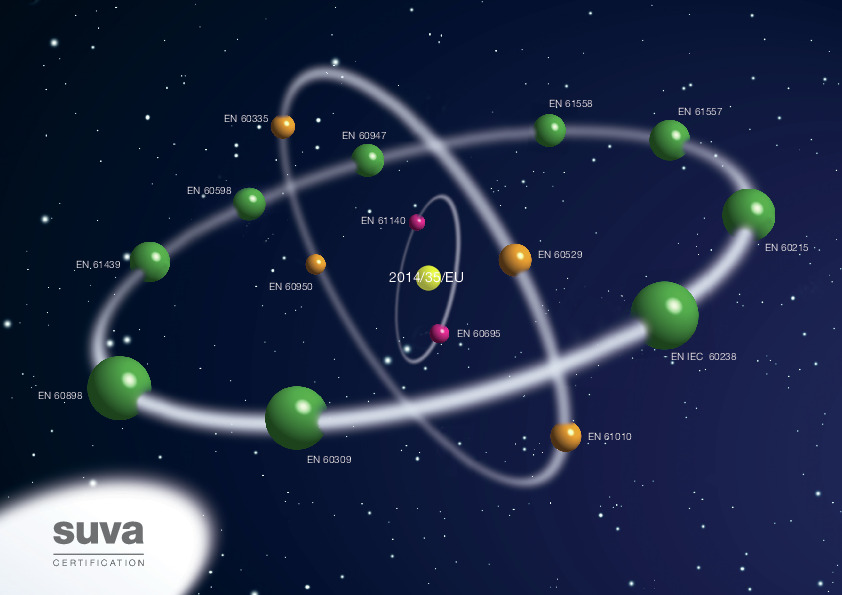

- The Machinery Directive obliges you as a manufacturer to assess and minimise risks.

- Our risk assessment tool guides you through this process step by step.

Assessing and mitigating risks – an overview of the Suva method

First determine the limits within which the product life of the machine operates – in particular the use, space and time limits.

Systematically identify all hazards, hazardous situations and hazardous events during all phases of life of the machinery.

In a risk analysis, identify the biggest risk of each hazardous situation. In each case, determine the extent and probability of occurrence of harm.

Decide which hazardous situations require further risk reduction. Determine whether the necessary risk reduction has been achieved, without introducing additional hazards or increasing other risks.

An inherently safe design measure is the first and most important step for mitigating hazards and reducing risks. The greatest advantage of inherently safe design measures is that they often remain effective throughout the entire service life of a machine.

If an inherently safe design measure is not able to mitigate hazards or reduce risks to a sufficient extent, technical protective measures must be taken. This involves distinguishing between guards and protective devices. Where necessary, additional protective measures may be required.

If risks still remain, you must draw attention to all of the remaining risks in the information for use. However, the information for use must not be a substitute for inherently safe design measures, technical protective measures or complementary protective measures.

In this three-step, iterative process, you will assess whether the protective measures chosen achieve the required level of risk reduction after each step. If they do not, implement the protective measures in the next step. If the required risk reduction cannot be achieved even after the third step, you must redefine the limits of the machinery.

Document the risk assessment and risk reduction. You will have to include this in the technical documentation.

The risk assessment and risk reduction procedure for machinery is explained in detail in the publication with order number 66037.

Risk assessment tool

Are you taking all the requirements of the Machinery Directive into account? Suva's online tool helps you to assess and minimise risks step by step.

Contacts

Downloads and orders

Search